PP815A 3BSE042239R2 3.8'' Overlay Touch Glass Repair

- Model

- PP815A 3BSE042239R2

Item specifics

- Warranty

- 365 Days

- Product Line

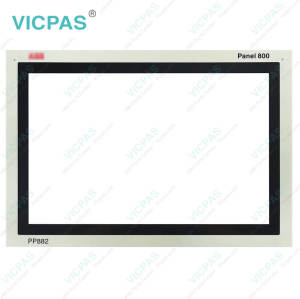

- Panel 800

- Types

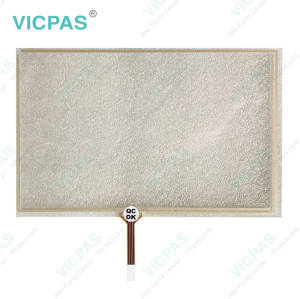

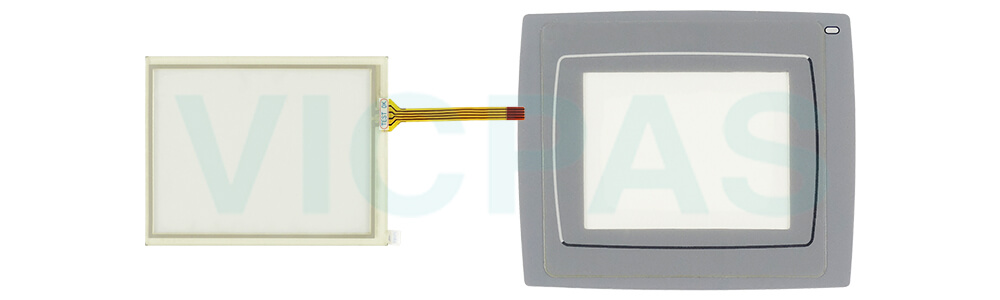

- Resistive Touch Panel and Protective Film

- Shipping

- 2-3 workdays

- Size

- 3.8 inches

Review

Description

Panel 800 PP815A 3BSE042239R2 Resistive Touch Screen Front Overlay Repair Replacement

Order each part separately is available

The Panel 800 operator panel is developed to satisfy the demands of humanmachine communication. Built-in functions such as displaying and controlling text, dynamic indication, time channels, alarm and recipe handling are included.

The operator panel work, for the most part, in an object-oriented way, making it easy to understand and use. The configuration operation of the panel is made in a personal computer, using the configuration tool Panel Builder 800. The project is then transferred and stored in the PP815A 3BSE042239R2 operator panel.

The PP815A 3BSE042239R2 operator panel can be connected to many types of automation equipment, such as PLCs, servos or drives.

VICPAS supply Panel 800 PP815A 3BSE042239R2 Touch Screen Monitor and Protective Film with 365 Days warranty and support Urgent Worldwide Shipping.

Specifications:

The table below describes the parameters of the PP815A 3BSE042239R2 Panel 800.

| Part Number: | PP815A 3BSE042239R2 |

| Touch Material: | Polyester on glass |

| Part Type: | New |

| Backlight: | LED |

| Warranty: | 365 Days |

| Diagonal (inches): | 3.8” widescreen |

| Overlay Material: | Autotex F157/F207 * |

| Active Area Of Display: | 70.1 x 52.6 mm |

| Display Resolution: | 320 × 240 pixels |

| Display Type: | TFT-LCD |

Related Panel 800 Terminals Part No. :

| Panel 800 | Description | Inventory status |

| PP825A 3BSE042240R3 | Panel 800 Series PP825A Touch Screen Protective Film Replacement | In Stock |

| PP845 3BSE042235R1 | Panel 800 PP845 Front Overlay Touch Membrane Repair | In Stock |

| PP845A 3BSE042235R2 | Panel 800 Series PP845A Touch Glass Front Overlay Repair | In Stock |

| PP846 3BSE042238R1 | Panel 800 Series PP846 Terminal Keypad Replacement Repair | Available Now |

| PP846A 3BSE042238R2 | Panel 800 PP846A HMI Membrane Keyboard Replacement | Available Now |

| PP865 3BSE042236R1 | Panel 800 Series PP865 Touch Screen Monitor Front Overlay | In Stock |

| PP865A 3BSE042236R2 | Panel 800 Series PP865A Front Overlay MMI Touch Screen Replacement | In Stock |

| PP865S 3BSE042242R1 | Panel 800 Series PP865S HMI Touch Screen Protective Film | Available Now |

| PP871 3BSE069270R1 | Panel 800 Series PP871 Protective Film Touchscreen Repair | In Stock |

| PP871 3BSE069270R2 | Panel 800 Series PP871 HMI Protective Film Touch Screen Glass | Available Now |

| PP874 3BSE069271R1 | Panel 800 Series PP874 Front Overlay Touch Screen Panel Repair | In Stock |

| Panel 800 Repair | Description | Inventory status |

Panel 800 HMI Manuals PDF Download:

FAQ:

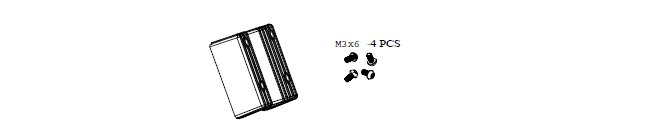

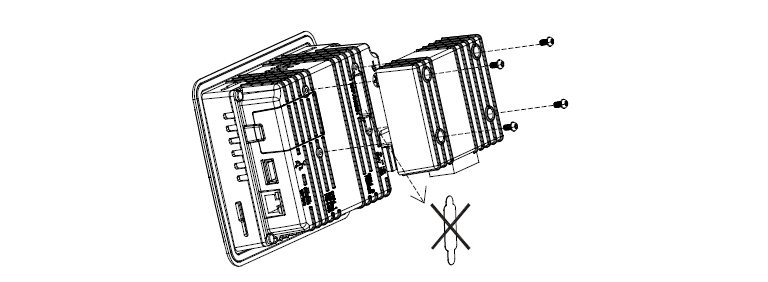

Question: How to install the PP815A 3BSE042239R2 operator terminal?

Answer:

1. Unpack and check the delivery. If damage is found, notify the supplier.

2. Disconnect the PP815A 3BSE042239R2 operator panel from the power supply.

3. Remove the plastic cover from the expansion port.

4. Secure the expansion module in position, using the provided screws.

5. Connect the PP815A 3BSE042239R2 operator panel to the power supply.

Question: How to ground the PP815A 3BSE042239R2 operator panel?

Answer:

1. The operator panel’s mounting clamps do not provide a secure grounding connection between the panel and the device cabinet.

2. Connect a 2.5 mm² wire between the operator panel’s quick-connect plinth and the panel chassis.

3. Connect a 6 or 4 mm² wire or grounding braid between the panel’s chassis and the closest grounding point on the door.

4. Connect a strong but short grounding braid between the door and the device cabinet.

5. Twist the cables onto the 24 V DC feed.

6. A ferrite core suppresses disturbances to the 24 V feed. 2 turns around the ferrite core provide 4 times the suppression of 1 turn. 3 turns around the ferrite core provide 9 times the suppression of 1 turn.

Common misspellings:

PP15A 3BSE042239R2

PP815A 3BSE04239R2

PP815A B3SE042239R2

PP815A 3BSE402239R2

PP815A 3BSE0422239R2