IS the Touchscreen equivalent to the Human Machine Interface (HMI)?

- Share

- From

- https://www.linkedin.com/company/guangzhou-vicpas-touch-technology-co.-ltd

- publisher

- https://www.facebook.com/vicpastouch/

- Issue Time

- Aug 29,2017

Summary

Vicpas mainly provide Touch Screen, Touch Panel, Membrane keyboard Switch Keypad for Siemens, Allen Bradley, B&R, KUKA, Beijer, ABB, Proface, Omron, Schneider, Mitsubishi, ELO, 3M Microtouch, Gunze, AMT, DMC and many other automation HMI panel replacement.

OEM is available for us. All of them are in stock, could be shipped out immediately via DHL, FEDEX, UPS, TNT, EMS, TOLL,.

Touch screen or Human Machine Interface (HMI)

What is Touch Screen Technology?

Types of Touchscreen Technology

Let us now give an engineer’s eye to this revolutionary technology. A touchscreen is a 2 dimensional sensing device made of 2 sheets of material separated by spacers. There are four main touchscreen technologies:

1) Resistive

2) Capacitive

3) Infrared

4) Surface Acoustic Wave

1

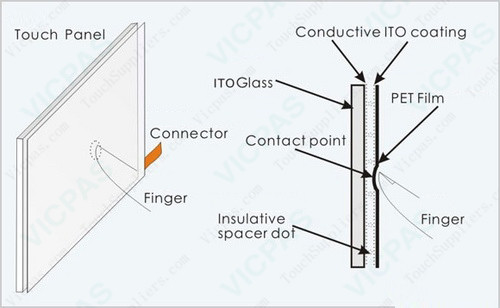

Resistive Touchscreen Technology

The resistive touchscreen consists of a flexible top layer made of Polyethylene (PET) and a rigid bottom layer made of glass. Both the layers are coated with a conducting compound called Indium Tin Oxide (ITO) and then spaced with spacers. While the monitor is operational, an electric current flows between the two layers. When a touch is made, the flexible screen presses down and touches the bottom layer. A change in electrical current is hence detected and the coordinates of the point of touch is calculated by the controller and parsed into readable signals for the operating system to react accordingly.

Some of the popular devices that use Resistive Touchscreen are Guangzhou Vicpas Touch, Siemens, B&R Power panel,Allen Bradley, B&R, KUKA, Beijer, ABB, Proface, Omron, Schneider, Mitsubishi, ELO, 3M Microtouch, Gunze, AMT, DMC,etc.

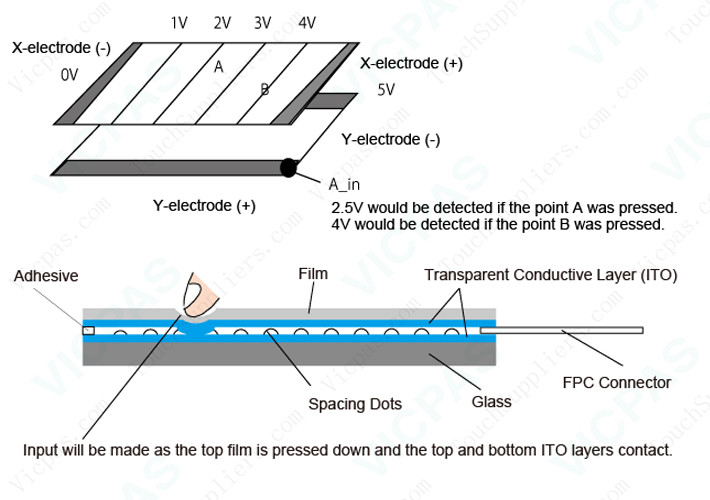

These systems transmit only 75% of light from the monitor. The resistive touchscreen is further divided into 4-, 5-, 6-, 7- and 8-wired resistive touchscreen. While the constructive design of all these modules is similar there is a major distinction in each of its method to determine the coordinates of touch.

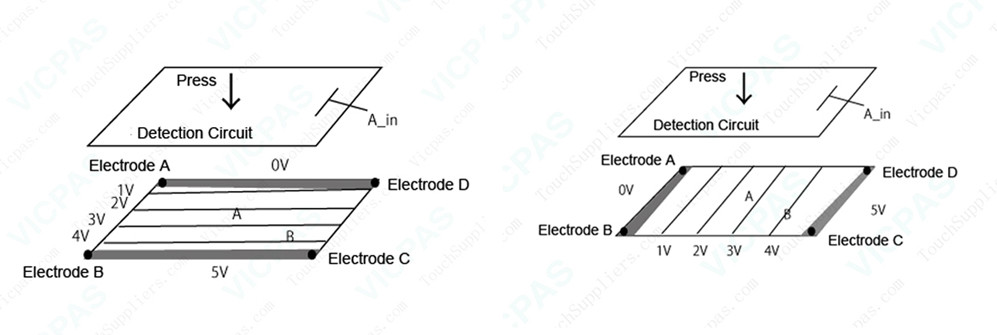

- 1.The Four-wire Resistive Touchscreen uses both the layers to calculate the axes information of the touch. Touch measurement in the 4-wire is a 2 step process. The x-coordinate of the touch point is calculated by creating a voltage gradient on the flexible layer, and the y-coordinate is determined by creating a voltage gradient along the bottom layer.

Pros and Cons: Consequently, the 4-wire resistive touchscreen is less durable, feebly accurate and can drift with environmental changes. However these negatives are divulged only with large-sized touchscreen. These are relatively cheap, easily available and consume low power. - 2.The Five-wire Resistive Touchscreen do not uses the coversheet (flexible layer) in determining the touch coordinate. All the position sensing is employed on the stable glass layer. In this design, one wire goes to the coversheet and four wires are deployed to the four corners of the bottom sheet. The coversheet only acts as a voltage measuring probe. The functioning of the touchscreen remains unscathed even with changes in the uniformity of the conductive coating over the coversheet.

Pros and Cons:Highly durable, accurate and reliable. This technology involves complex electronics and is expensive. However, it can be used in sizes upto 22”. - 3.The Eight-wire Resistive Touchscreen is simply a variation of the 4-wire one with the addition of 4 sense wires, two for each layer. The sensing points aid in reducing the environmental drift to increase the stability of the system. The 8-wire systems are employed in sizes of 10.4” or larger where the drift can be significant.

- 4.The Six and Seven wire resistive touchscreen is also a variant to the 5 and 4 wire technology respectively. In the 6-wire resistive touchscreen an extra ground layer is added behind the glass plate which is said to improve system’s performance. While, the seven–wire variant has two sense lines on the bottom plate. However, these technologies are as prevalent as their counterparts.

2

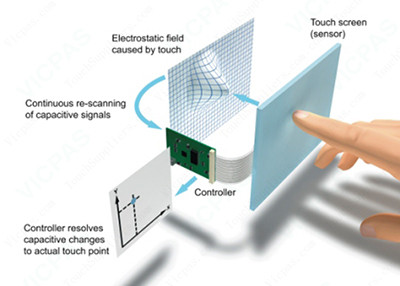

Capacitive Touchscreen Technology

The Capacitive Touchscreen Technology is the most popular and durable touchscreen technology used all over the world at most. It consists of a glass panel coated with a capacitive (conductive) material Indium Tin Oxide (ITO). The capacitive systems transmit almost 90% of light from the monitor. Some of the devices using capacitive touchscreen are Motorola Xoom, Samsung Galaxy Tab, Samsung Galaxy SII, Apple’s iPad. There are various capacitive technologies available as explained below.

Surface-Capacitive screens, in this technique only one side of the insulator is coated with a conducting layer. While the monitor is operational, a uniform electrostatic field is formed over the conductive layer. Whenever, a human finger touches the screen, conduction of electric charges occurs over the uncoated layer which results in the formation of a dynamic capacitor. The computer or the controller then detects the position of touch by measuring the change in capacitance at the four corners of the screen.

Pros and Cons: The surface capacitive touchscreen is moderately durable and needs calibration during manufacture. Since a conductive material is required to operate this screen, passive stylus cannot be used for surface capacitive touchscreen.

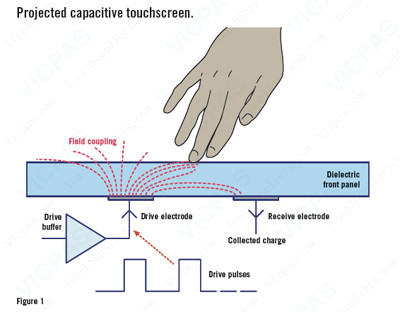

In the Projected-Capacitive Touchscreen Technology, the conductive ITO layer is etched to form a grid of multiple horizontal and vertical electrodes. It involves sensing along both the X and Y axis using clearly etched ITO pattern.

The projective screen contains a sensor at every intersection of the row and column, thereby increasing the accuracy of the system. There are two types of projected capacitive touchscreen: Mutual Capacitance and Self Capacitance.

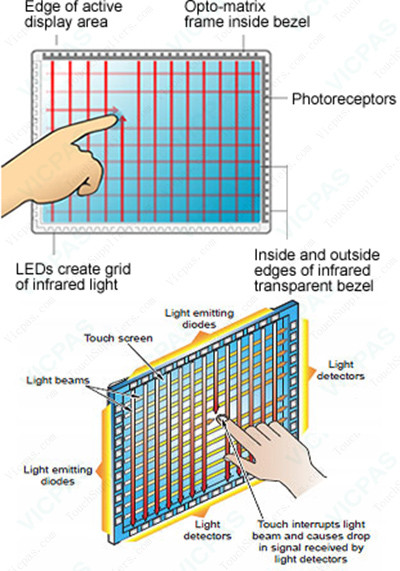

3Infrared Touchscreen Technology

In the Infrared Touchscreen Technology, an array of X- and Y- axes are fitted with pairs of IR Leds and photo detectors. The photo detectors detect any change in the pattern of light emitted by the Leds whenever the user touches the monitor/screen.

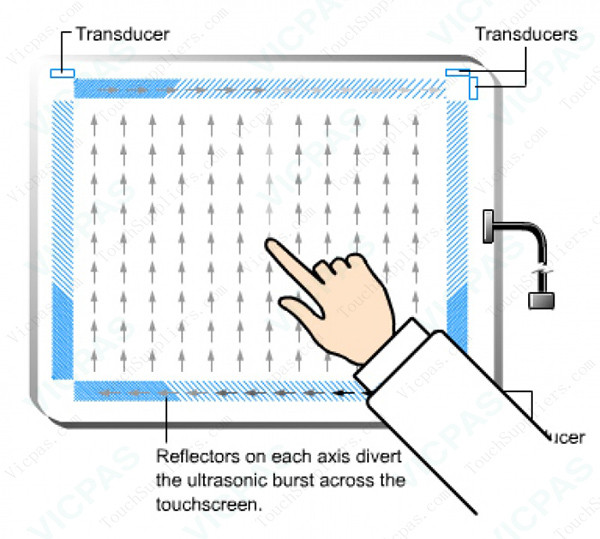

4Surface Acoustic Wave Touchscreen technology

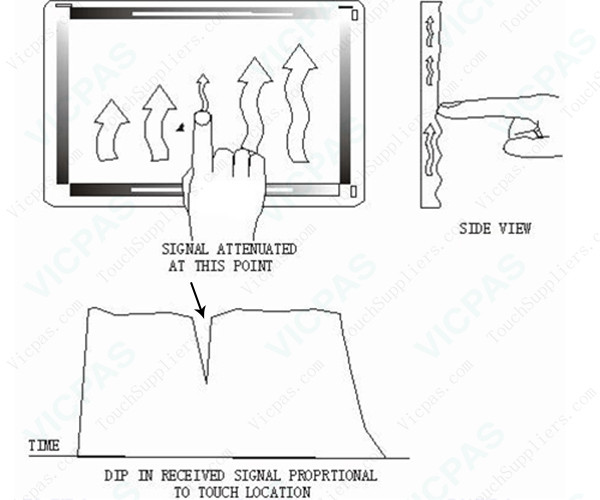

The Surface Acoustic Wave Touchscreen technology contains two transducers (transmitting and receiving) placed along the X-axis and Y-axis of the monitor’s glass plate along with some reflectors. The waves propagate across the glass and are reflected back to the sensors. When the screen is touched, the waves are absorbed and a touch is detected at that point. These reflectors reflect all electrical signals sent from one transducer to another. This technology provides excellent throughput and image clarity.

Pros and Cons: 100% clarity is obtained as no metallic layers are present on the screen, it can be operated using passive devices like stylus, glove or finger nail. Screen can get contaminated with much exposure to dirt, oil which may haunt its smooth functioning.

Who is the best touch screen / touch panel supplier?

Guangzhou Vicpas Touch Technology Co., Ltd. is a renowned and professional Touch screen Panel, Keyboard membrane and Accessories manufacturer in a global spectrum.

After more than 10 years of accumulated experience and continuous improvement of quality control, at the same time a reliable strategic partner and supplier of worldwide top companies.

Vicpas's success depends on customers support, provide One-stop shop service with the win-win relationships for touch screen, touch panel, membrane keyboard and LCD Display. Since entering the global market, we have continued to set up new standards for reliable performance, exquisite design and customer service.

As a professional OEM/ODM supplier, we have modern machines and scientific management system guarantee high quality and on time delivery.Vicpas total output of Touch screen panel and Keyboard membrane Accessories reach 500,00pcs per month. Our products are mainly exported to more then 60 countries, especially European and America.

Vicpas’s concept is to provide superior ratio of price and quality products for our partners and customers to strengthen their competence in their local markets.

Vicpas Touch will be one of your best strategic business partners in Faucet industry in China.

Guangzhou VICPAS Touch Technology CO.,LTD

Guangzhou City, Guangdong Province, P.R.China

Tel : +86-158-7652-5394

Fax : 0086-020-38837509

Website : www.vicpas.com

Email : Jack@vicpas.com sales@vicpas.com

Follow us on Social Media to get the latest update and promotion information!