A-B-B Teach Pendant Troubleshooting: Common Issues and Fixes

- Share

- Issue Time

- Nov 24,2025

A-B-B Teach Pendant Troubleshooting: Common Issues and Fixes

By Vicpas Industrial Automation Experts | Published: November 24, 2025

Table of Contents

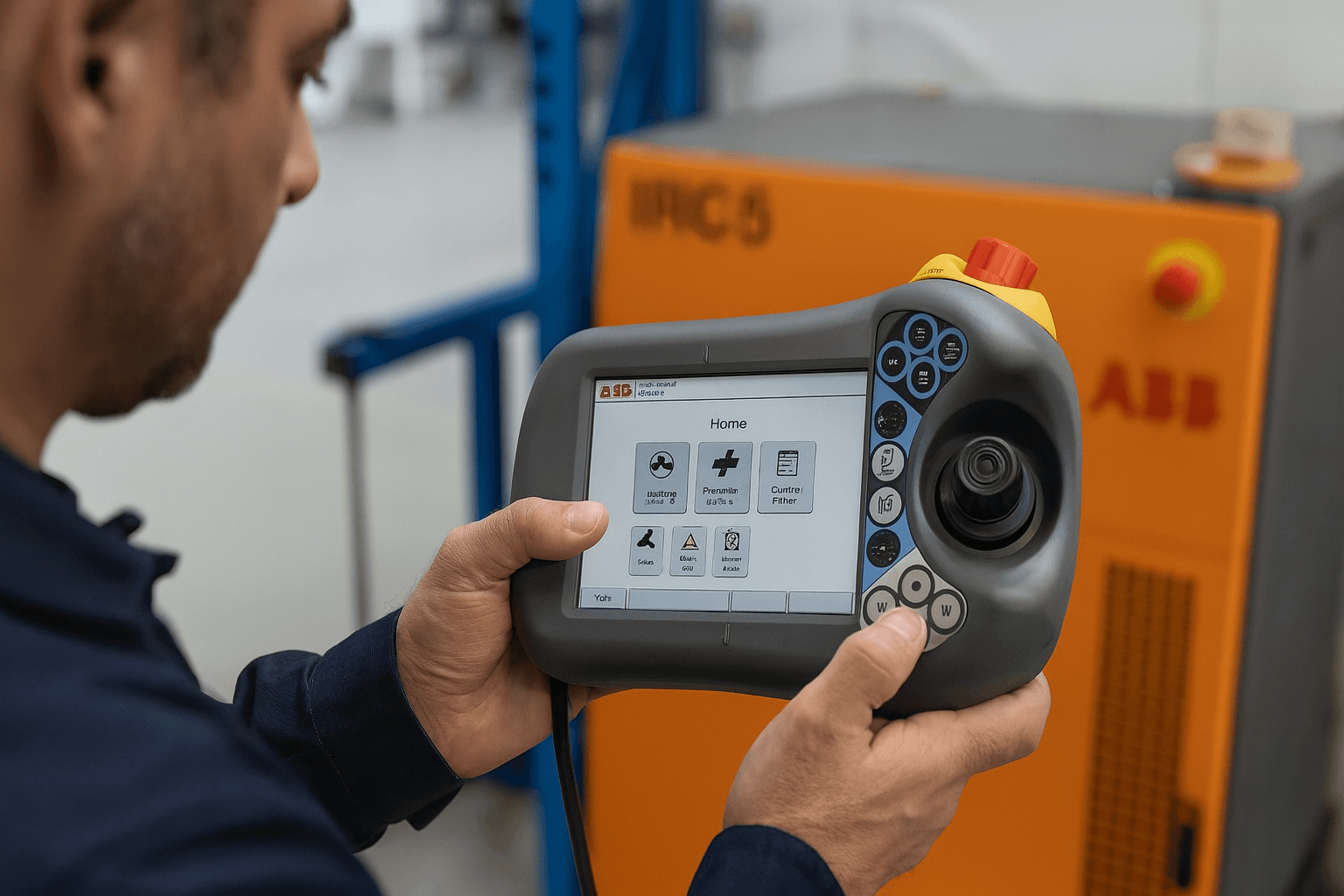

As a leading global supplier with over 15 years specializing in A-B-B robot spare parts and repair, Vicpas has helped thousands of factories minimize downtime. This guide compiles the most complete, real-world-tested solutions for A-B-B Teach Pendant (FlexPendant) problems.

Need parts immediately? Click here for A-B-B Teach Pendant parts — touch screens, membranes, cables, emergency stop switches — 365-day warranty + 24h worldwide shipping.

Why A-B-B Teach Pendant Issues Happen and How to Spot Them

According to the official A-B-B IRC5 Troubleshooting Manual and thousands of real cases, more than 80 % of FlexPendant failures fall into the four categories below — almost all of which can be solved quickly with the right steps.

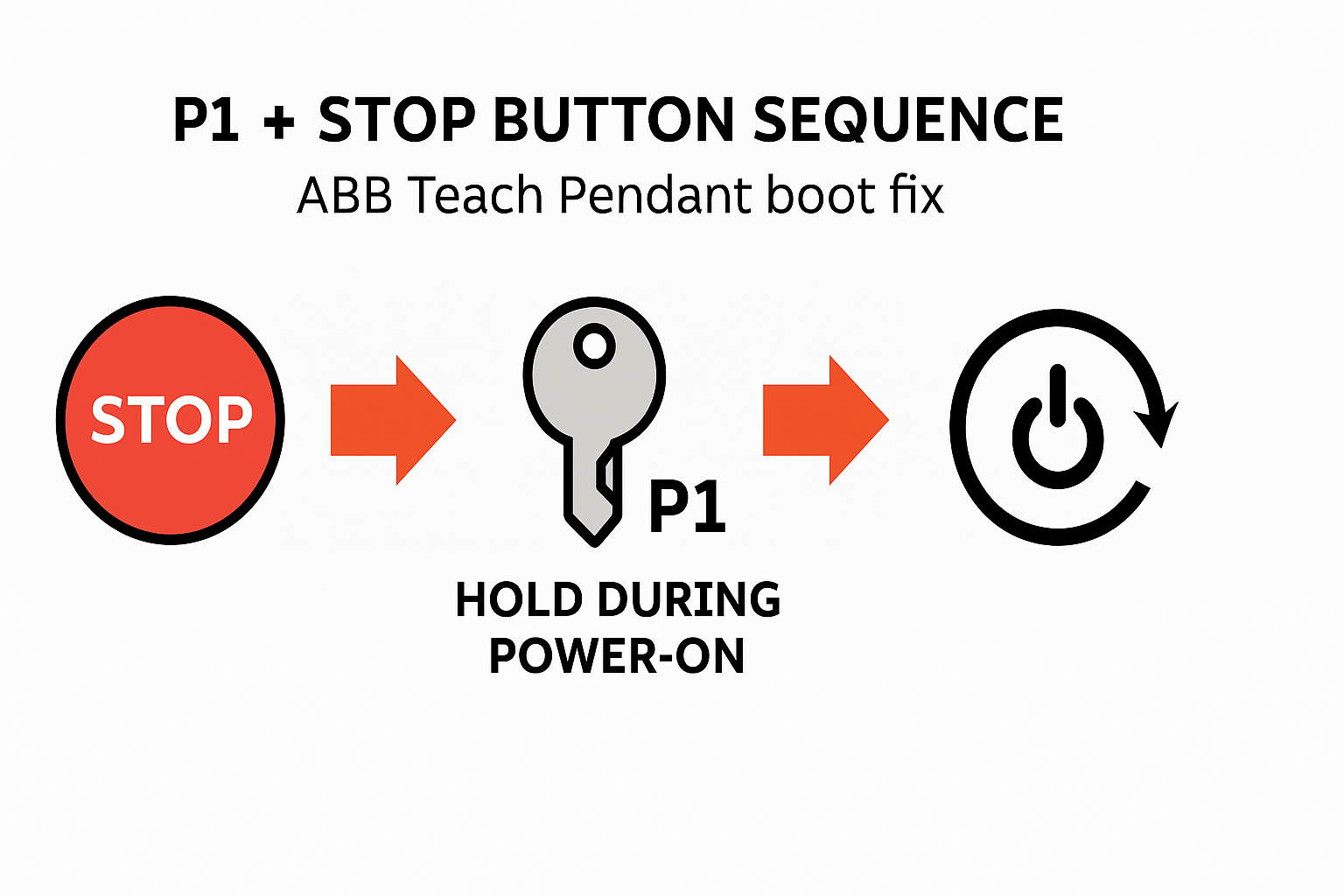

Issue 1: Stuck on Boot Screen / Boot Failure

One of the most frustrating problems is when the FlexPendant gets stuck on the boot screen or freezes indefinitely at “Starting application”.

Causes

- Corrupted TPU image or flash disk from power interruptions

- Loose internal connections (especially display ribbon cable)

- Firmware mismatch after failed updates

Official A-B-B Recommended Fixes

- Power cycle the entire system (30 seconds off)

- Press and hold Stop + P1 (and enabling device) while powering on → forces complete image reload

- Wait 5–12 minutes for completion

- Check event log for remaining alarms

Issue 2: Frozen on “Connecting to Controller” or Communication Failures

Your A-B-B Teach Pendant powers on but freezes at “Connecting to Controller,” preventing any robot interaction. Community discussions highlight this as a frequent post-commissioning problem.

Causes

- Faulty network cables or loose connections between pendant and IRC5 controller

- Main computer module failure or SD card errors in the host

- Safety chain interruptions triggering alarms like 20240 (emergency stop)

Step-by-Step Fixes

- Hard Reset: Press the small reset button on the pendant’s back (pinhole) while controller runs, or unplug/replug the cable

- Ethernet Verification: Inspect LEDs — green pulsing indicates healthy link. Swap cables and test ports

- B or P Startup: Attempt “B” (basic) or “P” (partial) boot via controller panel. Avoid “I” startup unless factory reset is desired

- Alarm Reset: Clear 10012/10013 by ensuring all safety devices are closed and switching to Motors ON

For persistent issues, our Vicpas repair kits include high-durability Ethernet cables (3HAC047665-002) — browse catalog.

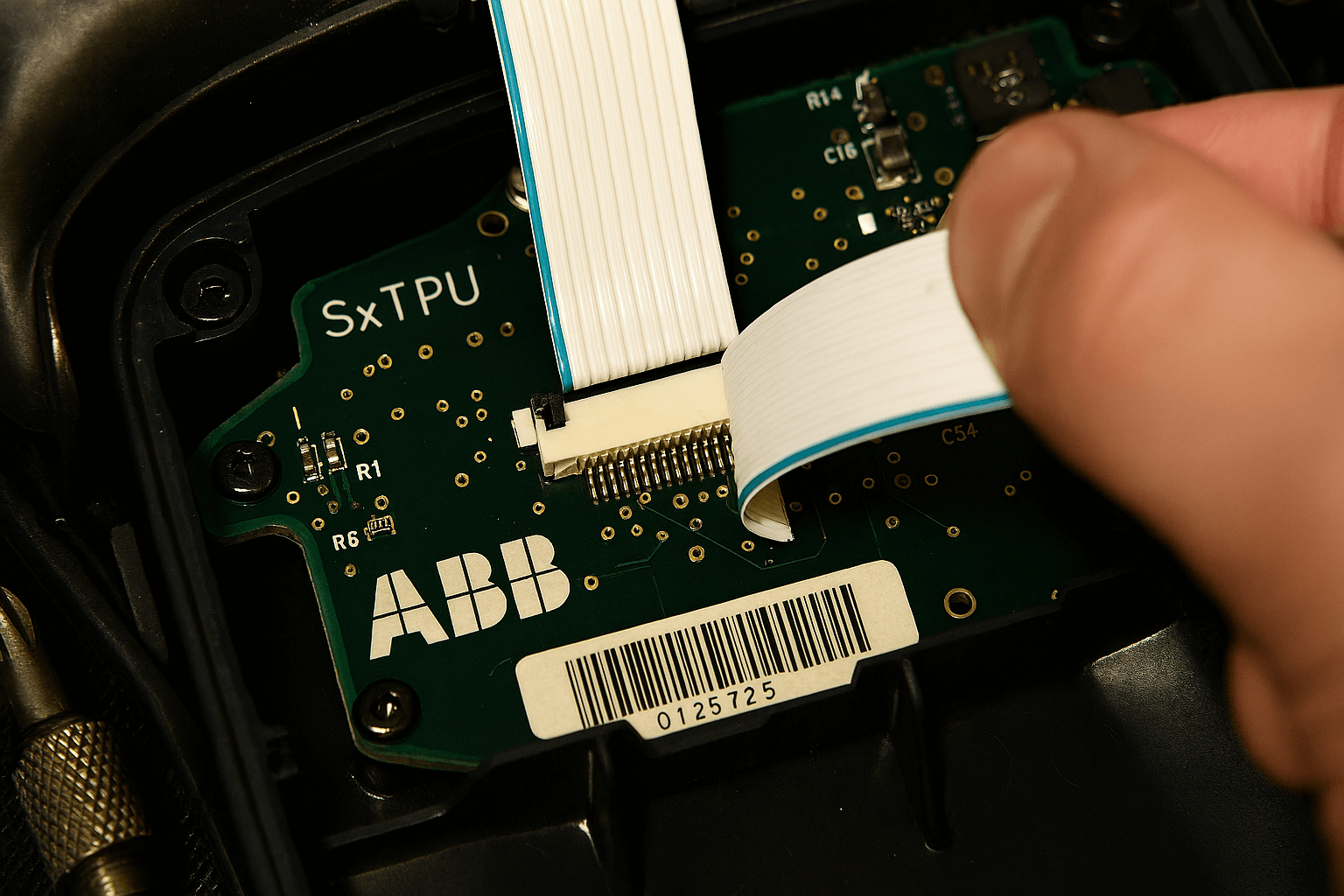

Issue 3: White Screen / Blank Display

A blank white startup screen on your A-B-B Teach Pendant, despite the robot running smoothly, screams display hardware trouble. Forums pinpoint this to internal ribbon cable shifts, especially after handling mishaps.

Causes

- Loose or unseated display ribbon cable in the SxTPU board

- Backlight power-saving mode or driver calibration errors

- Overheating or ESD damage (always use wrist straps per A-B-B safety guidelines)

Step-by-Step Fixes

- Reseat Connections: Power off, open the pendant (if comfortable), and gently push the ribbon cable back into its slot. Secure with Kapton tape

- Power and Backlight Check: Verify 24 V supply from DSQC 662; reset breaker F5 if voltage low

- Firmware Reload: Use P1 + Stop method to reflash

- Test Swap: Connect a known-good pendant to confirm controller health

Issue 4: Touchscreen Unresponsive or “Robotbootappl.exe” Crash

Touch inputs ignored or crashes like “Robotbootappl.exe has stopped working” are common.

Causes

- Dust on acoustic reflection stripes blocking signals

- Faulty touch matrix, control card, or signal lines

- Software crashes from incompatible drivers or high CPU loads

Step-by-Step Fixes

- Clean reflection stripes with soft cloth (no liquids)

- Recalibrate touch in Settings → Calibration

- Reboot with P1 + Stop to reinstall image

- Replace digitizer if physically damaged — Vicpas supplies pre-calibrated units

When to Call in the Pros: Advanced Repairs for Stubborn A-B-B Teach Pendant Issues

If DIY steps fail, deeper problems like PCB damage, battery failures, or bus communication errors may lurk. Professional services handle these with SMD/THT component swaps and simulated robot testing.

While options like K+S Services or Neethsel HK excel in screen and power repairs, Vicpas stands out with A-B-B-specific expertise: We source genuine-compatible parts globally, ensuring 100 % uptime compatibility.

Explore our Teach Pendant solutions for everything from emergency stop switches to full refurbishments — backed by our commitment to quality and fast delivery.

Final Tips for Preventing A-B-B Teach Pendant Downtime

- Routine Maintenance: Clean screens monthly, secure cables, and update firmware quarterly.

- Safety First: Always release the enabling device if malfunctions occur, and work in manual mode within arm reach.

- Backup Plans: Keep spare parts handy — Vicpas ships worldwide in 24 hours.

Facing an A-B-B Teach Pendant Headache?

Don’t let it slow your operations. Visit Vicpas today for expert advice, or shop our premium Teach Pendant parts.

Shop Parts NowContact Vicpas for Immediate Support

Share your troubleshooting wins in the comments below — we’re here to help!

References & Further Reading

- FlexPendant DSQC 679 stuck on booting – RobotStudio Forum

- Robotbootappl.exe crashed – Robot-Forum

- Frozen on “Connecting to Controller”

- White startup screen – ribbon cable fix

- P1+Stop recovery method

- ABB Official IRC5 Troubleshooting Manual (PDF)

- K+S Services – ABB Teach Pendant Repair

- Neethsel HK – Industrial Teach Pendant Repair

Vicpas: Empowering Industrial Automation with Precision and Reliability.