FANUC Teach Pendant: Troubleshooting Guide and Expert Solutions

- Share

- Issue Time

- Aug 8,2025

FANUC Teach Pendant: Troubleshooting Guide and Expert Solutions

Introduction to FANUC Teach Pendant Issues

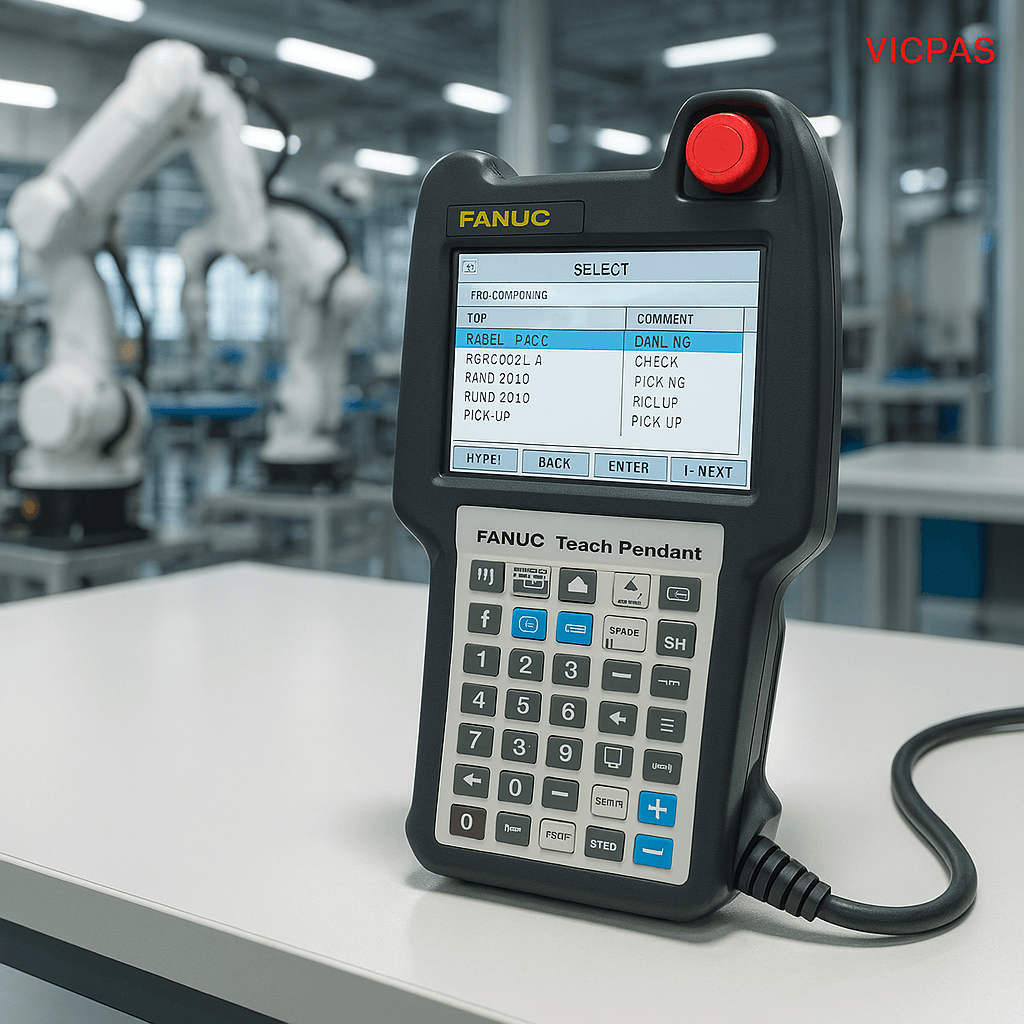

The FANUC Teach Pendant is an essential tool for programming and operating FANUC robots, widely used in industries like automotive, electronics, and logistics for tasks such as robot movement, program editing, and system monitoring. However, issues like black screens, unresponsive buttons, or error codes can disrupt operations. This guide, brought to you by Vicpas, a trusted supplier of industrial automation components, provides expert troubleshooting steps to resolve common FANUC Teach Pendant problems, ensuring minimal downtime and optimal performance.

Common FANUC Teach Pendant Issues and Solutions

1. Black Screen or Failure to Power On

A black screen or a Teach Pendant that won’t turn on is a frequent issue, often caused by power supply problems, cable issues, or internal faults.

Troubleshooting Steps:

- Check the Cable Connection: Ensure the Teach Pendant cable is securely connected to the controller. A loose or damaged cable, such as those connecting to the R-30iB controller, can cause power issues. Test continuity with a multimeter or swap with a known working cable.

- Inspect the Power Supply: Verify the 24V power supply to the pendant is stable. An unstable voltage or power board failure can prevent the pendant from powering on.

- Fuse Check: A blown fuse in the controller, such as Fuse2 on the R-30iB PLUS, may cause the pendant to fail. Replace the fuse and check the E-stop board.

- Firmware Compatibility: Ensure the pendant’s firmware matches the controller’s. A mismatch can prevent booting. Perform a cold boot by holding F1 and F5 during power-up to access the boot monitor menu and update firmware if needed.

Vicpas Solution: At Vicpas, we offer high-quality replacement FANUC Teach Pendant cables and refurbished pendants, such as the A05B-2255-C101, compatible with R-30iB controllers. Our parts undergo rigorous testing to ensure like-new performance at 50-75% less than OEM prices. Visit Vicpas FANUC Teach Pendant Products for reliable spares.

2. Unresponsive Buttons or Deadman Switch Issues

Unresponsive buttons or a faulty deadman switch can halt manual operations, often due to wear, dirt, or circuit issues.

Troubleshooting Steps:

- Clean the Button Surface: Gently clean buttons with a soft cloth to remove dirt or impurities. Severe wear may require replacing the button membrane or board.

- Check the Deadman Switch: For errors like SRVO-230/231 (Chain 1-2 abnormal), repeatedly engage and disengage the deadman switch. Reset the single-channel fault via the alarm menu (F3 key).

- Inspect Internal Circuits: Aging or damaged internal circuits can cause button signal failures. Consult a professional technician for circuit board diagnostics.

Vicpas Solution: Vicpas provides replacement button membranes and repair kits for models like A05B-2518-C202#ESW, ensuring restored functionality. Our components are sourced globally and meet strict quality standards. Learn more at Vicpas.

3. Error Codes: SRVO-007 External Emergency Stop Alarm

The SRVO-007 alarm indicates an external emergency stop condition, often triggered by a misconfigured E-stop circuit or faulty wiring.

Troubleshooting Steps:

- Verify E-stop Connections: Check the E-stop buttons on both the pendant and controller. Ensure they are not stuck or pressed. Reset both E-stops after powering on the controller.

- Inspect Wiring: Examine the E-stop circuit wiring for loose connections or shorts, particularly in the controller’s E-stop board.

- Consult Documentation: Refer to the FANUC R-30iB Mate Maintenance Manual for wiring diagrams and reset procedures.

Vicpas Solution: Our team at Vicpas offers technical support and replacement E-stop boards for FANUC controllers, ensuring quick resolution of SRVO-007 errors. Contact us at Vicpas Support for assistance.

4. Slow Performance or Obsolete Models

Older Teach Pendant models, such as those for R-J3 or R-J3iB controllers, may become slow or incompatible with newer robots, leading to operational inefficiencies.

Troubleshooting Steps:

- Upgrade to iPendant: Consider upgrading to the FANUC iPendant, which features a touchscreen and enhanced graphics for faster programming.

- Perform Backups: Regularly back up CNC parameters and PMC data to prevent data loss during upgrades or repairs. Use USB or PCMCIA for backups.

- Check Compatibility: Ensure the pendant model (e.g., A05B-2255-Cxxx for R-30iB) is compatible with your robot series, such as R-2000iC or ARC Mate 100iC.

Vicpas Solution: Vicpas stocks a wide range of refurbished and new FANUC iPendants, compatible with modern controllers like R-30iB Plus. Upgrade affordably at Vicpas FANUC Teach Pendant Products.

Preventive Maintenance Tips for FANUC Teach Pendants

To prolong the life of your FANUC Teach Pendant and minimize issues, follow these maintenance practices:

- Regular Cleaning: Clean the pendant’s screen and buttons regularly to prevent dirt buildup.

- Battery Replacement: Replace the controller’s main battery annually and the motherboard battery every 2-3 years to avoid power-related issues.

- Grease Robot Joints: Use the correct grease for your robot to reduce wear, which can indirectly affect pendant performance. Refer to FANUC’s maintenance guidelines.

- Firmware Updates: Keep the pendant’s firmware updated to ensure compatibility with the controller and avoid black screen issues.

- Training: Invest in FANUC training to master Teach Pendant operations and troubleshooting. FANUC offers over 100 tutorials for hands-on learning.

Why Choose Vicpas for FANUC Teach Pendant Solutions?

At Vicpas, we specialize in providing high-quality FANUC Teach Pendant replacements, repair kits, and accessories, ensuring your robotic systems run smoothly. Based in Guangzhou, China, with global shipping capabilities, Vicpas is a trusted supplier for industries worldwide, offering:

- Cost-Effective Parts: Save 50-75% compared to OEM prices with our refurbished and new Teach Pendants, including models like A05B-2518-C202#ESW and A05B-2256-Cxxx.

- Rigorous Testing: All components undergo comprehensive refurbishment to meet OEM standards, ensuring reliability and performance.

- Expert Support: Our team provides technical guidance for troubleshooting and maintenance, helping you resolve issues quickly.

- Wide Compatibility: Our products support a range of FANUC robots, including R-Series, M-Series, and ARC Mate Series.

Explore our full range of FANUC Teach Pendant solutions at Vicpas FANUC Teach Pendant Products and keep your operations running efficiently.

Additional Resources

- FANUC Official Support: Access technical support and manuals at FANUC America.

- FANUC Tutorials: Learn programming and troubleshooting with FANUC’s free video tutorials.

- Community Forums: Join discussions on Robot-Forum or r/Fanuc on Reddit for peer advice.

Conclusion

The FANUC Teach Pendant is a critical component for industrial automation, but issues like black screens, unresponsive buttons, or error codes can disrupt productivity. By following the troubleshooting steps outlined above and partnering with Vicpas, you can resolve problems efficiently and maintain optimal performance. Visit Vicpas for high-quality replacement parts, repair kits, and expert support to keep your FANUC robots running smoothly.

References

- FANUC Robot Technical Support - Official FANUC support page.

- FANUC Robot Series R-30iB Mate + Mate Plus Maintenance Manual - Comprehensive maintenance guide.

- FANUC Alarms: Diagnosing & Tracking Robot Faults - Motion Controls Robotics article.

- SRVO-230/231 Chain 1-2 Abnormal - RoboJob knowledgebase.

- Resolving FANUC Pendant Black Screen & System Entry Problems - InRobots repair guide.

- Guide to Fanuc Teach Pendant Replacement and Repair - FanucWorld guide.

- Teach Pendant Not Turning On - Robot-Forum thread.

- Troubleshooting FANUC SRVO-007 External Emergency Stop Alarm - YouTube diagnostic video.

- Emergency Support - Aerobotix FANUC alarm explanations.

- R-30iA Teach Pendant Not Turning ON - DIY-Robotics forum post.